Methanol Fuel Supply Units

Methanol is one of the most viable marine fuels to reduce Greenhouse Gas emissions and help the shipping industry meet decarbonisation targets. Indeed, full carbon neutrality is possible through the use of “green methanol”. Not only does methanol reduce CO2, but also SOx, NOx, and Particulate Matter, so it is a truly sustainable solution. With the Energy Efficiency Design Index (EEDI) and impeding emissions reduction requirements in mind, the use of methanol as a maritime fuel is and will continue to gain momentum in maritime.

In addition to this, methanol has the following benefits:

- Existing infrastructure can be used for storage as there are no specific temperature or pressure requirements

- Although methanol has lower volumetric energy density than LNG, the tank arrangements for methanol can still fit in a smaller space as no cryogenic or high pressure tanks are required

- Methanol is water soluble, and readily biodegradable

Built on Auramarine’s technical fuel supply system expertise

The methanol fuel supply unit is designed based on the technical capabilities of our advanced fuel supply management systems. On this solid foundation, we have built expert knowledge about methanol fuel system requirements in dialogue with leading engine makers and ship owners.

Auramarine’s methanol fuel supply unit is suitable for both two-stroke and four-stroke engines.

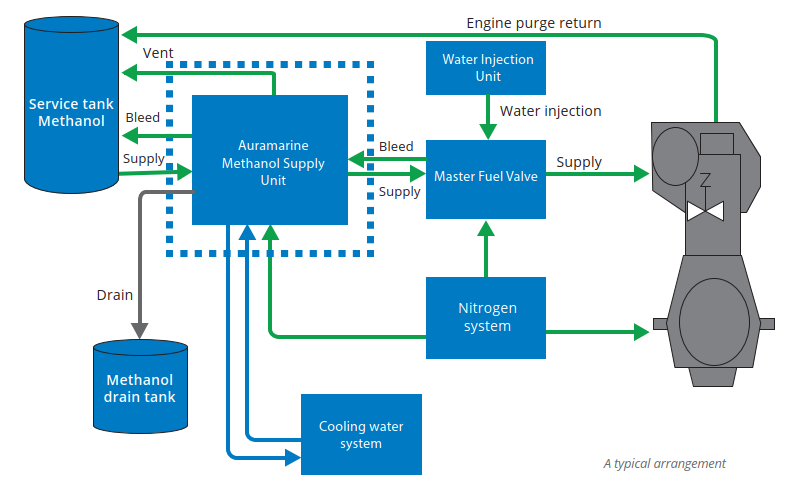

Our unit supplies methanol from the service tank to the engines and other methanol consumers.

It regulates fuel pressure and actively maintains the supply pressure within the specified tolerances during load changes. It also regulates the fuel temperature and filtrates the fuel to prevent any impurities from entering the fuel consumer.

Benefits for shipyard and installation

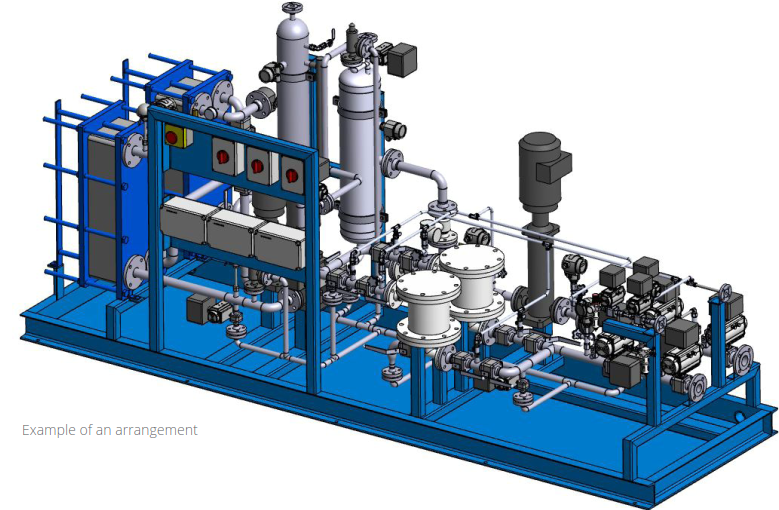

- Clear, modular and installation-friendly designs

- Pre-tested units shorten installation and commissioning times

- Classification certificate is delivered for the full fuel supply unit

- The design can be optimised for the exact space available

Benefits in operation

- Consistent, high-quality design and components ensure reliable and safe operation

- Duplex filter enables filter replacement when unit is in operation

- Fuel consumption metering is available via flow meter

- Spare part services ensures the availability of right parts at right time

Safety

Methanol is toxic and a low flashpoint fuel. Therefore, the fuel supply unit must be designed to meet the strict safety requirements for materials, components, assembly, operation and maintenance:

- All fuel supply system materials and manufacturing procedures are designed suitable for methanol service and for the specifications of a particular application

- The unit, its components & electrical equipment is designed to be installed in closed and Ex rated hazardous areas. All IECEx & Health & Safety Guidelines (HSE) have been taken into account

- The unit has a self-draining mechanical design, nitrogen inerting, and double block and bleed arrangement for all serviceable methanol line segments

- The electrical cabinets, control panels and variable frequency drives are designed to be placed separately to safe area