Helicopter refueling systems

The aim of a Helicopter refueling system is to store the fuel in the portable aviation refueling tanks and supply it to an aircraft free from water thanks to the filtration elements.

Detegasa supplies standard and bespoke Helicopter Refuelling Systems fully designed, manufactured and tested in compliance with civil aviation authority standards CAP 437 and CAP 748, related to the requirements for the fuelling of helicopters on offshore installations and vessels.

All of our offshore refuelling systems are built to meet the customer’s exact and specific requirements.

Detegasa’s Helicopter Refueling System is designed to handle the extreme conditions and requirements of offshore platforms whereas meeting the high demands for safety and reliability in harsh environments.

Main features and advantages

- Compliance with the requirements of the most recognized Classification Societies

- Suitable for JET A-1, JP5, JP8,AVCAT,TR1 and other different kind of military fuels

- Explosion-proof components

- Defuelling system available

- Customized solutions specially adapted to meet any customer need

Components

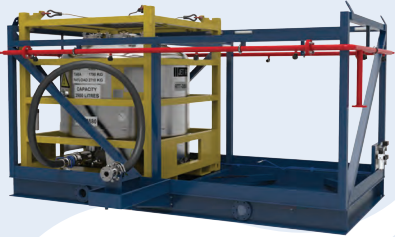

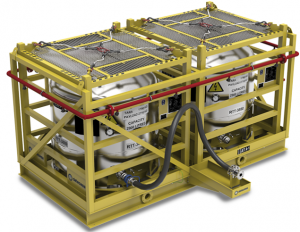

Laydown skid

- has been designed to install the portable tanks, the static storage tanks and the pump unit

- Components are to be protected by a deluge system against fire

- manufactured in mild steel in a continuous welded construction, in order to form a rugged unit

- equipped with a drip tray over the whole area, lifting lugs, buffer frame and deluge with spray nozzles

- can be customized for different confi¬gurations

Portable tanks

- available in different capacities

- manufactured in stainless steel and DNV GL type approved

- designed according to DNV 2.7-1, IMDG-T4, EN 12079, ASME VIII Div.1

Dispenser unit

- has been designed to assure a safe and easy operation

- includes a Filter Separator and Water Monitor or a combined Three-Stage Filter Vessel, Flow Meter, Local Control Panel, Filling Nozzle, Grounding System, Manual or Automatic Hose Reel and Yellow Amber Flashing Light

- Components are cased in a water proof cabinet with a roller shutter door

Pump unit

- for transferring fuel from the Fuel Tank(s) through the dispensing unit at a minimum flow rate of 225 litters/min at 3,5 bar pressure

- Includes a redundant pumping system (electrically or pneumatically actuated for a fixed or adjustable transfer)

- Customization is also available