Ballast water treatment

BIO-SEA designs and manufactures complete ballast water treatment systems, which combine mechanical filtration and high UV dose disinfection without any chemical treatment. They are made with high marine quality components.

Mechanical filtration technology

At first the system cleans ballast water by using a screen filter in order to reduce the amount of total suspended particles (organic or not) which are present in the seawater.

UV disinfection technology

The system disinfects the water and eliminates all microorganisms. Without any additional chemical products or active substances, the water passes through a reactor where UV rays destroy the microorganisms DNA.

Automated technologies

All operations of the ballast water treatment plants are monitored and controlled automatically by sensors.

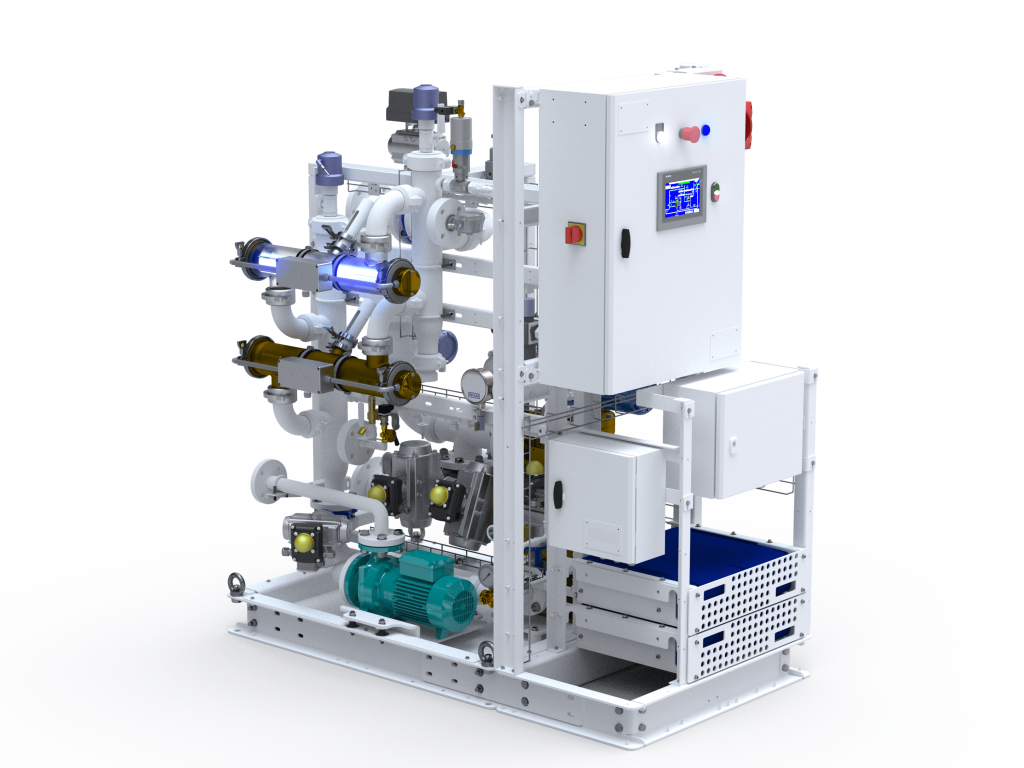

Compact range for small flow rates:

the BIO-SEA L “Easy-to”Fit” – from 10 to 120 m3/h

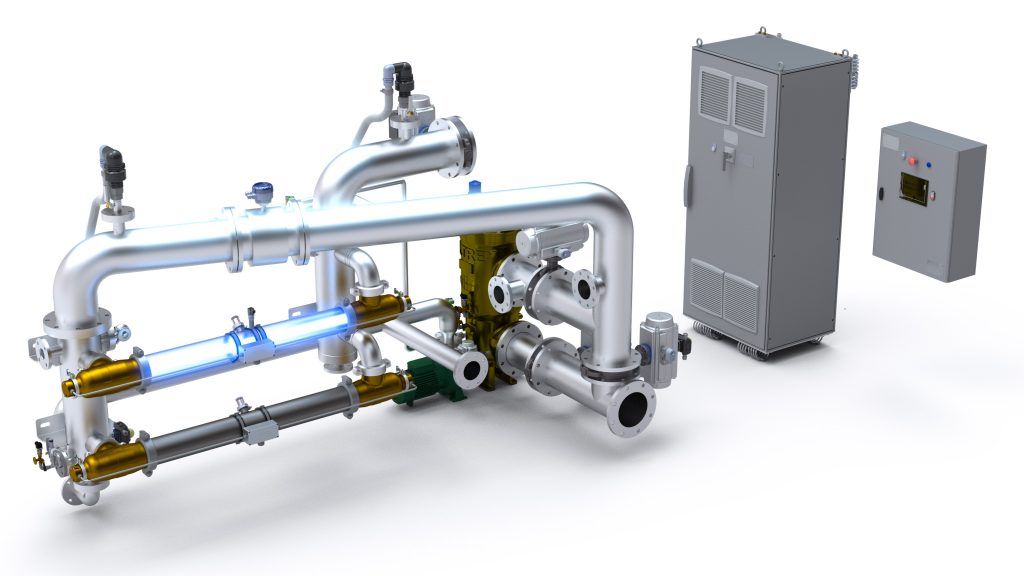

Standard range for larger flow rates:

the BIO-SEA B – from 55 to 2000 m3/h

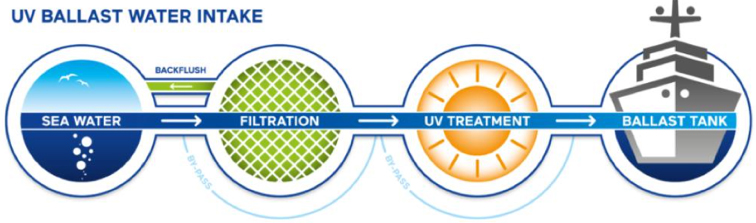

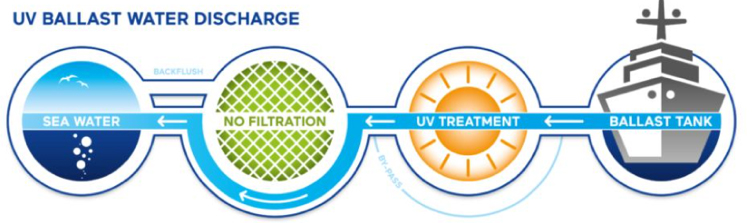

Treatment during ballasting operations:

During ballasting the operations of filtration and UV disinfection are carried out to limit the loading of suspended solids and living microorganisms in the ballast tanks.

Treatment during de-ballasting operations:

While de-ballasting, only the UV disinfection is done. This allows re-treating the water that stayed in the ship's ballast tank during the journey in order to eliminate the possible biological re-growth and to ensure compliance with the IMO standards.

UV disinfection only - filtration is automatically by-passed.

Cleaning Operations:

At the end of operations (either ballasting or de-ballasting) a full and automated cleaning of the system is performed. Afterwards the filter and UV reactors are getting flushed and filled with fresh water.

Available in modular (loose components) or SKID versions