Fuel Supply Systems

Heavy Fuel Oil (HFO) supply units

· a wide range of capacities

· multiple optional functions

· Flexible component arrangements accommodate units in the space available

Standardised AMB-Mc -series units for compact spaces

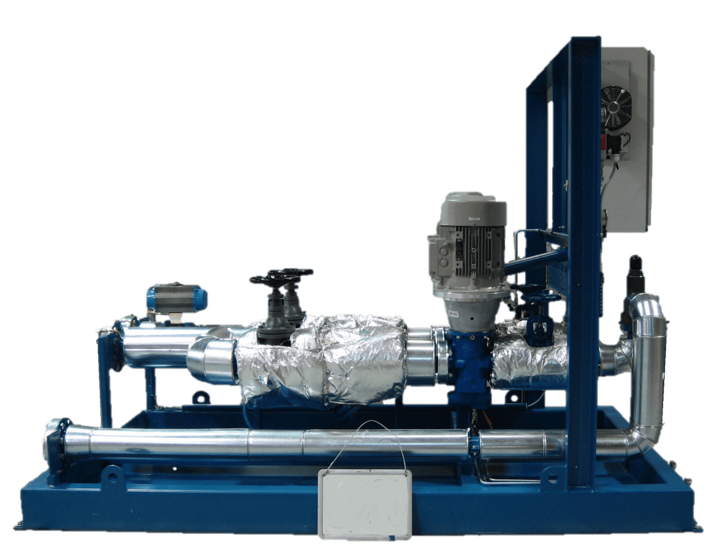

Auramarine fuel supply unit AMB-Mc Key benefits and features of AMB-MC-02/03/05/07 series units:

· Cost-savings through standardised components

· Easy maintenance: access is only required at the front and right-hand side of the unit

· Maximum power serviceable: approx.10MW

· Standard option comprises separate feeder and booster components

· Can be used to supply fuel to either main or auxiliary engines

· Dimensions, including service space: 1.50m x 2.90m

Customer-specific solutions with AMB-M –series

· Maximum power serviceable: 50MW

· Dimensions depend on the needed features and size, minimum 3,6x2,2m

· close co-operation to find the best solution for every project

· the units can accommodate a wide range of heaters, filters, pumps, flow meters and homogenisators to meet the customers requirements

· AMB-M units are designed to supply main and aux. engines reliably and simultaneously

Flexible installations, easily maintained

– Vielseitige Rohrleitungen an Vorder- und Rückseite der Anlage ermöglichen eine einfache Installation und nachträgliche Anpassungen

· the units are designed for easy access (maintenance space and location of displays and instruments)

Key benefits and features

· Can be extensively customised to meet all fuel system-specific requirements

· Proven reliability and safety from shell-type heaters and separate viscosity and temperature controls

· Fast, easy installation delivered through a compact design and versatile connections

· Easy operation: all important displays and instruments are visible at a glance

· Long and extremely reliable service life from quality components, carefully chosen materials and advanced manufacturing

Marine Gas Oil (MGO) supply units

· Usable for single-fuel MGO or multi-fuel systems

· Long-term reliability and operational performance

· MGO is cooled by a cooler unit, a chiller unit if needed and a cooling water circulation unit

Key benefits and features

· For operators looking to switch to low-sulphur fuels, Auramarine MGO supply units can be fitted to both new and existing vessels

· Easy and flexible installation either as independent components or a compact integrated unit, in both cases making good use of available free space

· Turn-key deliveries available

· Reliable, user-friendly operation

· Proven design and quality components

MGO units for retrofits

· MGO units can also be configured as retrofit units

· they are ideal for vessels with multi-engine configurations where one conventional booster is feeding two or more engines

· With the installation of an additional MGO unit, different engines can be operated on different liquid fuels

· The ability to readily change fuels is especially advantageous in the case of ships with scrubber installations

· The footprint of the MGO feeder-booster is remarkably smaller compared to a conventional HFO supply unit (space-consuming heaters, heavy automatic filters and thermal insulation are not required)

· Auramarine MGO supply units can be tailored as a feeder part connected to existing booster(s) or a fully independent complete MGO supply unit depending on the engine configuration.

Options

· A design option for constrained spaces which allows the unit to be split into two or three parts for smooth transport and installation

· Fuel oil system diagram update support

· Available for both seawater and LT water configurations

· Emergency pump available as an option

AUXILIARY UNITS

Emergency pump units (AEP)

Key benefits and features

· Rapid, reliable fuel supply is the first priority when managing a blackout scenario on any vessel

· AEPs ensure correctly pressurised fuel for problem-free operation when re-starting in blackout situations

· MDF is supplied via a pump driven by a pneumatic or electric motor

· pressurised air is controlled by a solenoid valve

A compact design makes it a natural choice, particularly in space-restricted areas

· AEPs are available as skid-mounted units or as part of an Auramarine fuel oil supply unit (AMB)

Cooling and chilling units (ACU, AMC)

Auramarine marine gas oil cooler units (ACU)

· Ensures the correct viscosity of MGO for the motor

· Plate or tube cooler types are available

· The units also contain relevant pipes, valves and measurement and display equipment

· Cooling water is delivered from vessel’s LT water, seawater cooling system or from a separate chiller unit

· The cooling process works with immediate temperature response

· The temperature change rate of the controller is set at 2°/min to prevent thermal shock (usable by changeover system or local manual control mode)

· Cooler units are available as SKID-module or integrated into the Booster unit (AMB)

Modular Chillers (AMC)

· AMCs cool down the fresh water in MGO water-cooling circuits

· Needed if not enough LT-water or seawater is available or if the fuel needs to be cooled below 40°C

· The complete chilling system can be customized

· As standard it consists of a compressor, condenser and evaporator, filters, a control panel and all necessary fittings and valves for installation and operation

· Pump modules provide the necessary chilled water flow for cooler units in the closed chilled-water circuit

Auramarine feeder unit (AMF)

· Designed to supply fuel oil to HFO/MGO booster units

· Contains of two main pumps, an operating pump and a standby pump

Tailored units

If the standard products are not suitable Auramarine can offer tailored solutions for your fuel supply, fuel-conditioning and lubrication requirements

Examples of our tailored solutions:

· Modularised configurations

· MGO circulation supply units

· HFO circulation units

· Fine filter units

· Feeder units

· Fuel flow measurement modules

· Gas valve units for natural gas (NG)

Lubrication units

· Used for pumping, filtering, and when necessary for cooling of the lubrication oil

HT-water preheating unit (APU)

· Auramarine preheating units (APUs) heat the water used in an engine’s high temperature (HT)-water system

· Heat is generated via steam or burning thermal oil

· APUs are equipped with an associated HT-water circulation pump, which provides a continuous flow of heated water

· APUs are typically used to keep the engine block warm for easy start-ups and to avoid heat tension in the engine

· The water temperature is kept constant by a built-in self-actuating thermostatic controller located in the unit

· APUs can be remotely-controlled or operated from a control cabinet mounted on the unit

· Additional pressure gauges and a thermometer are available as optional extras

READY FOR 2020

Auramarine Brennstoffwechselsystem

Auramarine Fuel Changeover System